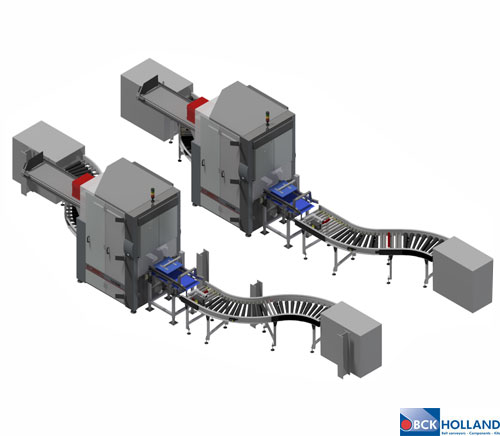

Smart and affordable layout solutions: BCK Holland unburdens all around Actitec Lid machines

Sarco Packaging B.V., specialist in machinery and packaging materials, faced a challenge with a customer: the logistical handling of boxes and crates around the Actitec lidding machine. The customer produces large-scale products for which accurate and fast processing space of packaging in flow was crucial.

That's where BCK Holland came in, a specialist in conveyor systems. The BCK Holland team understood that a perfectly functioning Actitec lidding machine only pays off with a well-organised logistics flow around it. With this assignment, they set to work to design a layout that seamlessly matched both the customer's needs and the Actitec lid machine's technology.

The customer was working within a limited space in which the transport systems had to be integrated, without disturbing the existing production line. In addition, it was essential to stay within a tight budget so that the investment could be recovered quickly.

BCK Holland developed a customised conveyor system that was both efficient and affordable:

- Compact conveyors that make optimum use of the available space. These conveyors ensured a smooth supply of boxes to the Actitec lidding machine, with advanced sensors ensuring perfect positioning.

- Integration with Sarco Packaging B.V. technology: The conveyor system was fully tuned to the speed and precision of the Actitec lidding machine, so that both systems worked synchronously.

- Modular construction: This made the system flexible, allowing it to be easily adapted in case of future expansions or changes in production.

- Cost savings: Through smart material choices and efficient design, BCK Holland managed to keep costs down without compromising on quality.

The result: a perfect collaboration

The new set-up resulted in much higher production efficiency, without downtime or logistical bottlenecks. The customer appreciated not only BCK Holland's technical expertise, but also their commitment and ability to think along within the confines of space and budget.

Thanks to the close cooperation between BCK Holland and Sarco Packaging B.V., this project showed how smart integration and customisation lead to maximum results. For the customer, it not only meant a smooth production process, but also peace of mind knowing that everything was perfectly organised.

Picture 1: