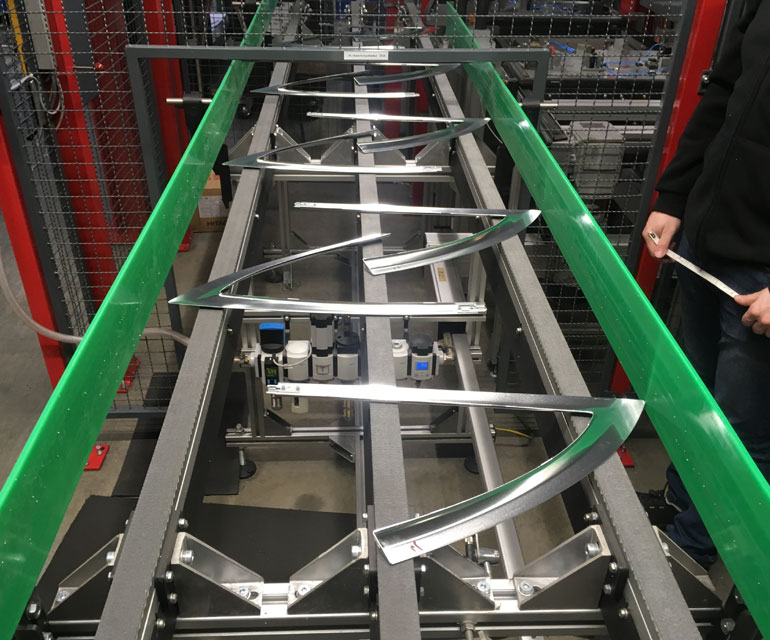

Timing belt conveyor type TB60

BCK Holland can supply timing belt conveyors in various versions, but for shorter delivery times, a standard has been developed, namely the type TB60. This has a standard timing belt width of approx. 80 mm and a frame width of approx. 90 mm (excluding bearing plates). The timing belt conveyor is driven by a 3-stage geared motor.

Terms of application

Environment: Dry and clean to slightly dirty

Load: max. 200 kg

Speed: Max. 75 m/min

Roller diameter: Standard Ø60 mm (Z20 - T10)

BCK timing belt conveyors are used, among other things, for transporting products or product carriers that need to be positioned. If there are several tracks, it also has the advantage that there is no speed difference between the different tracks and thus the product or product carrier does not twist on the various tracks.

A major advantage over belt conveyors is that there can be no slippage between pulley and timing belt and that a timing belt is less likely to derail than a belt material. In the past, the timing belt was often spurred with a V-belt or the timing belt pulley was fitted with 2 flanges. With a steering ring on the timing belt pulley, tracking a timing belt is significantly simplified and costs are reduced. To steer the timing belt, this principle uses a high-quality, wear-resistant plastic ring mounted around the timing belt pulley. With this steering ring, annoying flanges are unnecessary. Because the steering is much better, there is less wear and tear and machine breakdowns will be reduced.

BCK Holland can supply timing belt conveyors in various versions, but for shorter delivery times a standard has been developed, namely the type TB60. This has a standard timing belt width of about 80 mm and a frame width of about 90 mm (excluding bearing plates).

As with belt materials, various accessories, such as carriers or product carriers, can be welded onto timing belts. Besides welding accessories, it is also possible to connect them mechanically with a brass or stainless steel mechanical connector.

Technical specifications

- Basic: Aluminium frame

- Transport direction: unidirectional

- Toothed belt width: 80 mm

- Roller diameter: Ø 60 mm (standard, Z20-T10)

- Drive type: (in)direct end drive

- Motor position: Combination of left/right and pulling

- Speed: Max. 75 m/min (depending on version)

- Pulley design: Standard aluminium with Easy Drive® ring

- Geared motor: standard 3x230/400V, 50 Hz, IP55

- Toothed belt material: Choice from various brands, materials, frictions and colours

- Multiple tracks with 1 drive

- Drive shaft fitted with customer-specific shaft journals

- Other gearmotor configuration/brand

- Various toothed belt accessories such as carriers, strings or a mechanical connector

- Standard, telescopic or weighted undercarriage

- Chassis on adjustable feet or castors with brake

- Side guide (fixed or adjustable in green, black, blue or white)

- Electrical control