Roller conveyors

A roller conveyor, also called a roller conveyor or roller belt, is a transport system with rollers as the product carrier. A roller conveyor is mainly used to move a product from A to B manually, automatically or by gravity. Not all products can be transported on a roller conveyor. They are mainly products with a solid carrier surface where the pitch of the rollers is tailored to the smallest product. The products are usually boxes and crates. The BCK roller conveyors have a modular structure. As a result, BCK Holland B.V. is able to supply customised products with standard components. The application often determines whether it should be a gravity or a powered roller conveyor.

Types of roller conveyors

Each application or environment requires a different type of roller conveyor. BCK Holland supplies all kinds of customised roller conveyors. View part of our range below:

Powered roller conveyors

Environment: Dry and clean to lightly soiled

Load: Max. 100 kg/meter

Speed: Max. 36 m/min

Roller diameter: Ø50 mm

Gravity roller conveyors

Environment: Dry to damp and clean to slightly dirty

Load: Max. 150 kg/meter

Speed: n/a

Roller diameter: Ø20 / Ø30 / Ø50 mm

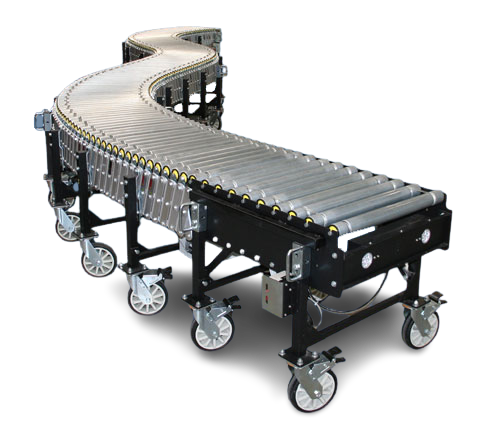

Powered flexible roller conveyors

Environment: Dry and clean to slightly polluted

Load: Max. 150 kg/meter

Speed: Max. 35 m/min

Roller diameter: Ø50 mm

Construction of a roller conveyor

A powered roller conveyor is a type of conveyor system used to efficiently move goods and materials in warehouses, production halls, distribution centers, and other industrial environments. It consists of a series of powered rollers that can transport goods from one point to another. Here is a general description of the construction of a powered roller conveyor:

-

Frame: The base of the roller conveyor is the frame, which is usually made of sturdy steel or aluminum to support the structure and provide stability.

-

Powered rollers: The conveyor has a series of rollers placed within the frame, with the rollers placed close together to create a continuous transport surface. These rollers are powered by electric motors, which drive the movement of the goods.

-

Electric motor and drive system: Typically, one of the rollers in the conveyor is powered by an electric motor. The motor can be powered by electricity or other forms of energy, depending on the specific application. The drive system ensures that the motor sets the rollers in motion.

-

Belt or chain drive: The electric motor may be connected to the rollers using a belt or chain. These drive mechanisms help transfer the rotational force from the motor to the rollers, making them rotate.

-

Control system: A powered roller conveyor is usually controlled by a control system, such as a Programmable Logic Controller (PLC) or a computer. This system controls the electric motors and can regulate the speed, direction, and start/stop functionality.

-

Supporting structures: In addition to the frame, there may be additional supporting structures to elevate the roller conveyor to the desired height and ensure stability.

The principle of a powered roller conveyor is relatively simple, but the specifications and designs can vary depending on the application and the weight and size of the transported goods. It can also be integrated with other conveyor systems, sorting systems, or pick-and-place systems to create a fully automated material handling system.

What is the difference between a belt conveyor and powered roller conveyor?

A belt conveyor and powered roller conveyor are both mechanical systems used to efficiently transport goods and materials within factories, warehouses and other industrial settings. However, they have different effects and properties. Here are the main differences between both systems:

BeltConveyor:

- Operating Principle: A belt conveyor uses a continuously moving belt (usually made of rubber, plastic, or metal) to transport goods from one point to another. The belt is typically driven by electric motors, keeping it in constant motion.

- Goods Support: Goods rest on the moving belt, meaning the surface on which the goods are transported is flat and continuous.

- Suitability for Various Goods: Belt conveyors are suitable for a wide range of goods, from small and light items to large and heavy materials.

- Applications: They are commonly used in manufacturing and distribution environments, food processing, airport baggage handling, and other industries where continuous transport is required.

Powered Roller Conveyor:

- Operating Principle: A powered roller conveyor uses sets of powered rollers to propel goods forward. These rollers rotate thanks to electric motors, pushing the goods along the conveyor.

- Goods Support: Unlike the band conveyor, goods do not rest on a flat surface but on the rotating rollers. This can be more effective for transporting goods that might not stay well on a belt.

- Suitability for Various Goods: Powered roller conveyors are especially suitable for transporting flat and sturdy objects such as boxes, crates, and pallets.

- Applications: Powered roller conveyors are commonly used in warehouses, distribution centers, postal sorting centers, and other situations where packages and heavy goods need to be efficiently moved.

In summary, band conveyors use a continuously moving belt and are suitable for a wide range of goods, while powered roller conveyors work with rotating rollers and are particularly suitable for transporting flat and sturdy objects. The choice between the two depends on the type of goods to be transported and the specific needs of the application.

Buy roller conveyor?

Are you interested in gravity or powered roller conveyors? BCK Holland has more than 15 years of experience in a wide variety of industries. That is why BCK Holland is able to give good advice and steer towards a good and affordable solution. Are you curious about the possibilities or prices of our roller conveyors? Then get in touch.

Roller conveyor photos

For inspiration or to estimate the possibilities at BCK Holland B.V., you can view many examples on this website.