Solutions transport systems

8. BCK Packing/repacking line for efficient packing in a compact space

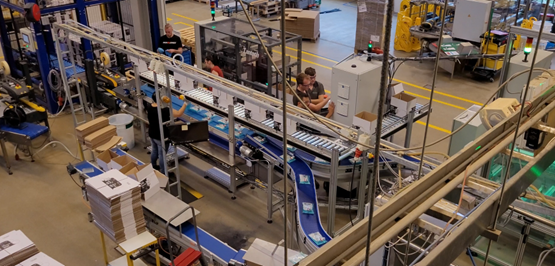

BCK Holland has delivered a compact and efficient packing line to a producer of hand hygiene products, efficiently integrating two production machines into one packing solution. The advanced solution allows two different production processes to run simultaneously, after which the products come together in one central packing line. This significantly increases production speed and reduces downtime, improving the overall efficiency of the production process.

The operation of the line is simple but effective. Products are fed onto the middle conveyor, while empty boxes are transported from the box erector to the upper conveyor. These empty boxes are placed on a linked table by a packer, where the products are then manually filled into the boxes from the middle lane. Once a box is completely filled, it is pushed to the lower discharge lane.

The filled box then passes through a carton sealer, which ensures a tight seal. Then the box is led on a conveyor belt to a coding unit, where the correct barcode is applied. Finally, the boxes are transported to a palletiser, which efficiently stacks the boxes for further distribution.

This automated packing line allows the manufacturer to process and pack a large volume of hand hygiene products with minimal manpower, while maintaining the speed and accuracy of the process.

Picture 1:

Picture 2:

Picture 3:

BCK Holland B.V.

Spuiweg 24

5145 NE Waalwijk

The Netherlands

[T] +31 (0)416 673880

sales@bckholland.com

www.bckholland.com

CoC: 18076783

VAT nr: NL813897075B01