Solutions transport systems

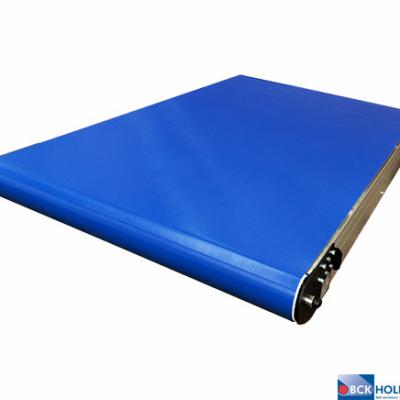

19. Incline belt conveyor with integrated metal detector

BCK Holland recently completed a delivery for a leading player in the plastic injection moulding market. The client produces high-quality plastic parts. Quality is crucial, and even the smallest metal particles in the plastic can negatively affect product performance and reliability.

With a production line running at full capacity, the customer was looking for a way to automate and optimise their quality control. In the plastic injection moulding process, metal particles can inadvertently enter the products, leading to rejects and costly production stops.

BCK Holland came up with a customised conveyor solution: a robust conveyor belt with integrated metal detector, perfectly tailored to the specific requirements of the injection moulding process. This system is designed to detect even the smallest metal particles in the plastic parts, without affecting the production speed.

The metal detector works with high precision, and as soon as contamination is detected the belt stops.

Since installing the conveyor belt with metal detector, the customer has dramatically increased their production efficiency. Automated quality control prevents contaminated parts from leaving the factory, resulting in less waste and fewer customer returns. Moreover, the system ensures a smooth production flow without interruptions, which is essential in the competitive plastics market.

BCK Holland has delivered not just another machine, but a total solution that allows the customer to continue to grow with confidence, while meeting the highest quality standards in the plastic injection moulding industry.

Picture 1:

Picture 2:

BCK Holland B.V.

Spuiweg 24

5145 NE Waalwijk

The Netherlands

[T] +31 (0)416 673880

sales@bckholland.com

www.bckholland.com

CoC: 18076783

VAT nr: NL813897075B01