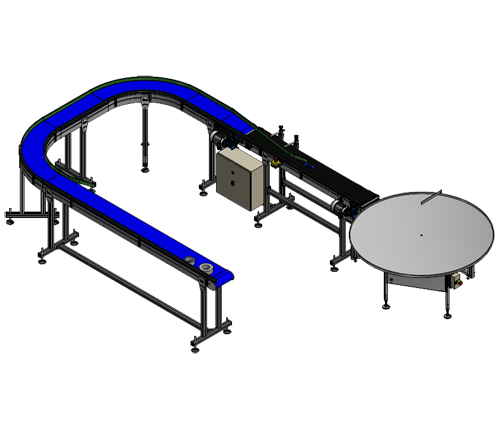

Stainless steel buffer tables

The BCK buffer tables, also called stainless steel turntables, are usually placed at the end of a production process for buffering products such as jars, cans, bottles, etc. The rotary tables are made of stainless steel as standard and are available with a blade diameter of 900 / 1,250 / 1,500 mm. The blade is also driven directly by the motor. This eliminates the need for chains and belts.

Types of stainless steel buffer tables

Buffer tables with a stainless steel top with a diameter of 900 / 1,250 / 1,500 mm are available from stock with a working height of 900 mm and equipped with an on/emergency switch off box with a 16A plug (400V).

Environment: Dry to damp and clean to slightly dirty

Diameter: 900 / 1,250 / 1,500 mm

Load: Max. 100 kg (evenly distributed)

Speed: Approx. 4 revolutions/minute

Plug-ready with 16A plug.

- frequency regulator with a 230V plug

- extra support wheels under the top

- adjusted working height

- castors with brake

Benefits of stainless steel buffer tables

There are many benefits to be gained by installing stainless steel buffer table, such as:- saving labour hours in the production process

- one operator can support several processes

- it contributes to a continuous production process